Sale!

20ft x 10ft SWIM SPA Plans – Commercial Size | Plans + Videos + Guide (Internal)

Original price was: $449.00.$149.00Current price is: $149.00.

**What’s Included:** –

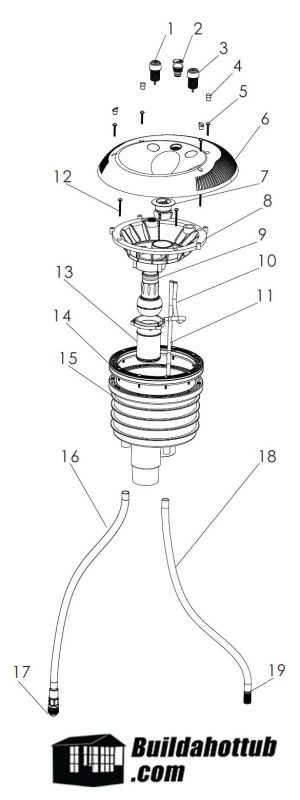

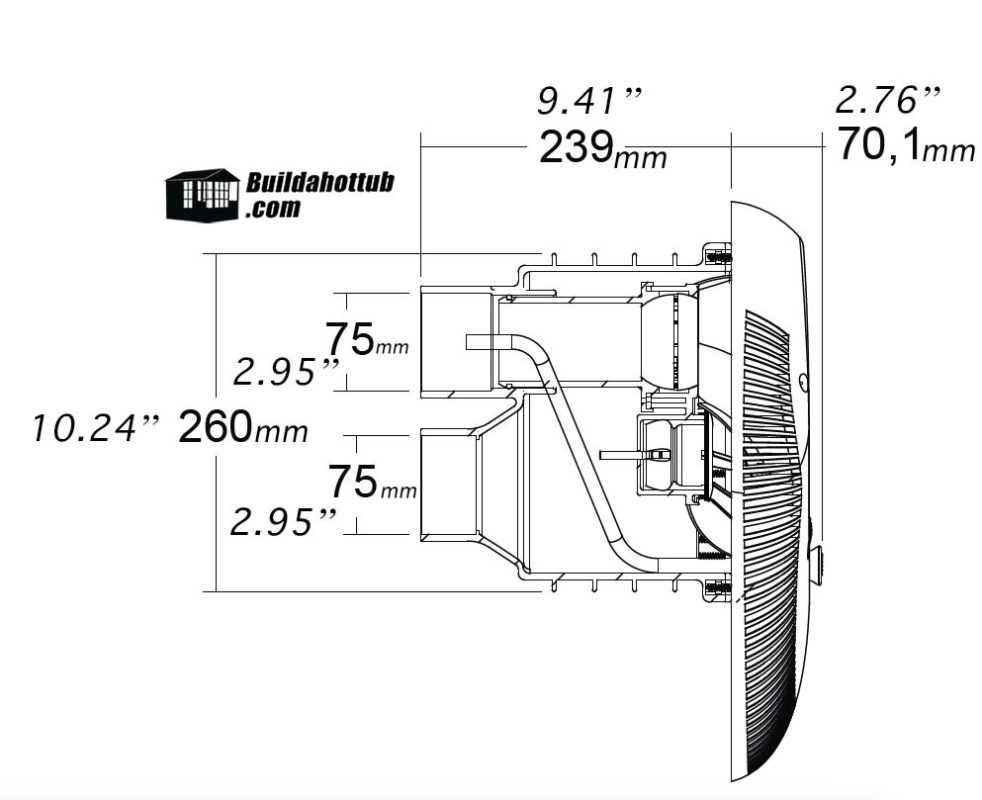

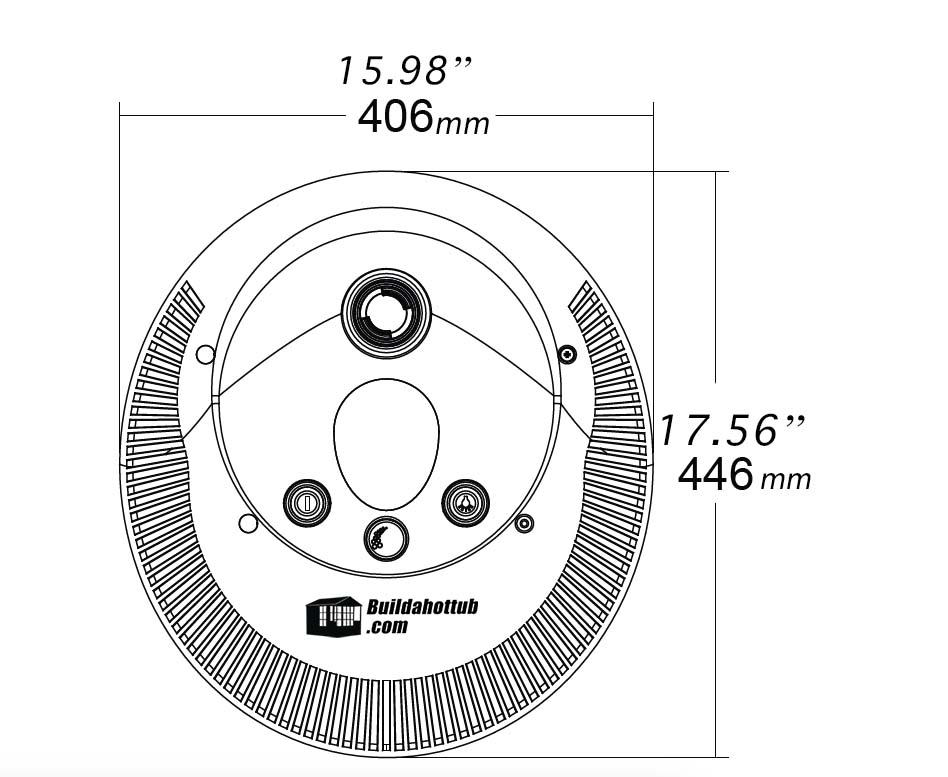

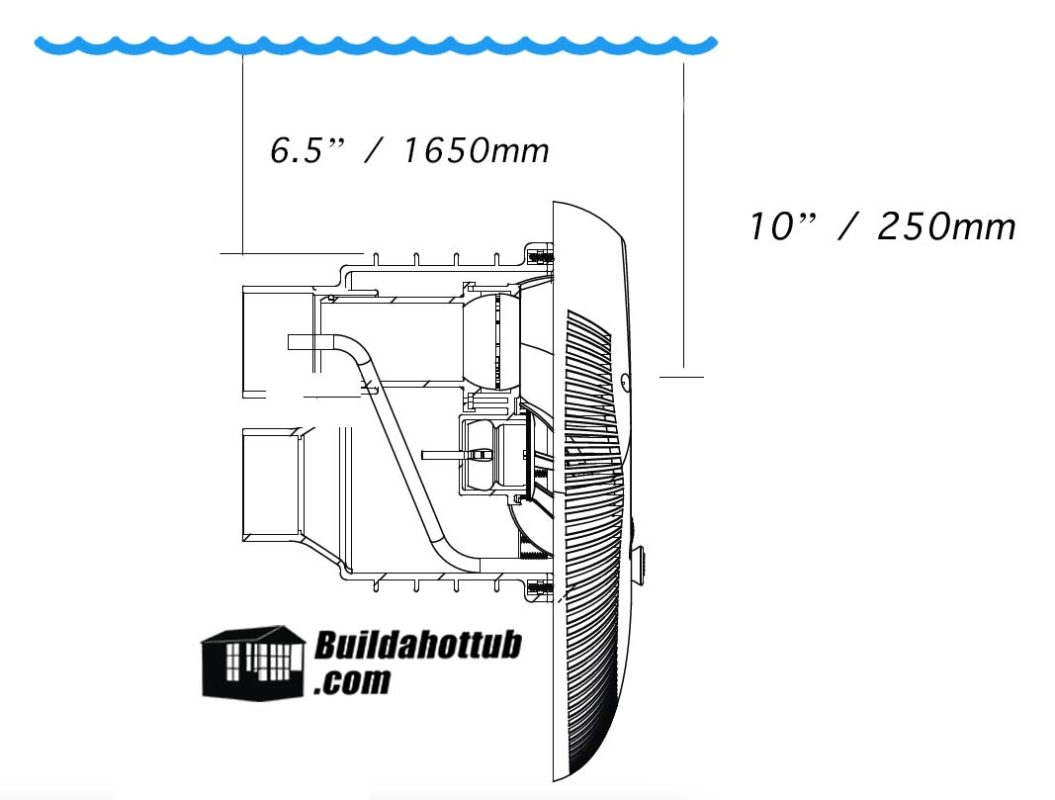

✅ Professional CAD designs

✅ Complete plumbing diagrams

✅ 130-page installation guide

✅ Video course (40+ lessons)

✅ Parts shopping list

✅ Lifetime email support

“These plans saved me $50,000 and the support was incredible!” – Kyle B., Colorado ⭐⭐⭐⭐⭐